メッセージ

Bringing special paper to the world

We are THE EXPERTS of "Japanese Washi paper"

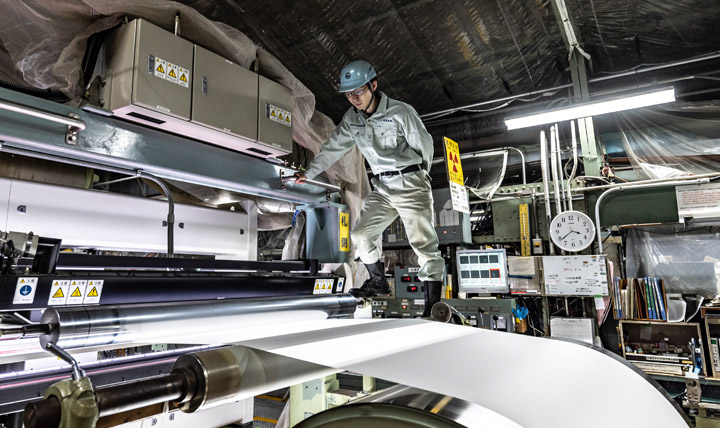

Daifuku Paper has been a developer and manufacturer of special paper since 1934 in Mino City, Gifu Prefecture, home of Hon-Minoshi (authentic traditional Japanese paper). We specialize in manufacturing base paper for industrial and household materials that combine Washi (traditional Japanese paper) manufacturing techniques with modern technologies. Our products range from base paper for masking tapes to Aluminum Electrolytic Capacitor Separator, we supply to both domestic and overseas customers. All of our products are “one and only” produced in an integrated system from development to mass production based on requests. Our outstanding Washi paper manufacturing technologies and expertise may change the future of your business.

Originated in Japan and nurtured over 1,400 years, Washi (traditional Japanese paper) has infinite possibilities. Our company can add functionality with our unique technologies while taking advantage of the excellent characteristics of Washi. It has a wide range of usage, and our ODM (Original Design Manufacturing) provide special Washi base paper for a variety of industries.

和紙の特性

- Machine-made Washi

- Thin Resistance Pliable

- Special technologies

- Powder mixing technology Double layer technology

Ultra-thin technology

Impregnation coating technology

Electronic

materials

Water treatment

related materials

Automobile

Construction

materials

Daily necessities

Pharmaceuticals

Plastic-free

| MOQ (Minimum Order Quantity) | From One metric ton (1,000kg) |

|---|---|

| Applicable basis weight | 10-50g/m2 (20-30g/m2 is our specialty) |

| Applicable raw materials | Wood pulp, Manila hemp, vinylon, polyester, etc. |

| Sheet formation | cylinder, short fourdrinier, cylinder x cylinder, cylinder x short fourdrinier |

当社の強み

POINT.01Streamline

We have an integrated in-house system, from proposing products, prototyping, raw material procurement to mass production. We have many examples of solutions in the past that were difficult for other companies to produce. You can definitely count on us anything about paper!

POINT.02Technical capabilities

We have our own processing technologies for special paper. We specialize in powder-mixed paper making and impregnation coating, which add various values to machine-made Washi paper. We provide unique products to customers in a wide range of fields, including electronic components, daily necessities and construction materials.

POINT.03Proposal ability

Please feel free to consult us for your needs. We can develop a product from improving your existing products or developing new products to measuring environmental solutions Plastic free. As a specialty paper professional, we offer ideas and products that exceed your expectations.

コア技術

Powder mixing papermaking technology

A technology of making paper by mixing various powders into Washi raw materials. They can be non-organic powders such as alumina and talc, metal foil or organic such as tea leaves. It is possible to produce special paper with functionality and design.

【 Product examples 】

Base paper for oil blotting paper, base paper for non-slip paper, base paper for various filters, base paper for upcycled paper, etc.

Double-layer papermaking technology

A technology of dividing raw material into two layers to make paper, then pasting together into one sheet before drying. This can prevent holes upon production process. Also, it is possible to create paper with different characteristics on the front and back by changing the raw materials for each layer.

【 Product examples 】

Base paper for food wrapping paper, base paper for art wrapping paper, etc.

Ultra-thin papermaking technology

The papermaking technology that creates strength while being ultra-thin inherits the tradition of Mino Washi. It is widely used for paper threads, separators, supports, etc. Stable mass production quality can be achieved with machine papermaking.

【 Product examples 】

Base paper for paper thread and paper cord, base paper for inner wrap, base paper for art printing, etc.

Impregnation coating technology

A technique to impregnate and apply water-based resins and chemicals to Washi paper. We have expertise in the selection and blending of raw materials and processing methods according to the purpose.

【 Product examples 】

Base paper for masking tapes, base paper for double-sided tapes, base paper for medical tapes, base paper for overlay paper, base paper for separators, etc.

製品事例

These are only examples. With our Washi paper manufacturing technologies,

we can create such "special paper"

-

Water resistant paper

-

Oil resistant paper

-

Heat resistant paper

-

Adhesive paper

-

Slip resistant paper

-

Tear resistant paper

-

Paper that does not conduct

electricity well

-

Environmentally friendly paper

工業用資材原紙

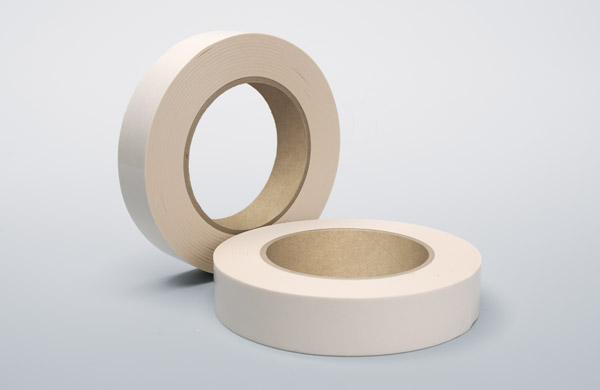

INDUSTRIAL.01Base paper for adhesive Washi tape

Many types of masking tape and sealing tape utilize base paper that benefits from the characteristics of traditional Japanese paper. Our products can satisfy customers who demand high quality for painting, packaging, medicine, electronic components, and more.

INDUSTRIAL.02Base paper for double sided adhesive tape

This is a low-density base paper that is uniform with no protrusions, allowing the adhesive agent to penetrate to the center of the paper. This is the one of our main products, and our paper-making technology has been developed over many years.

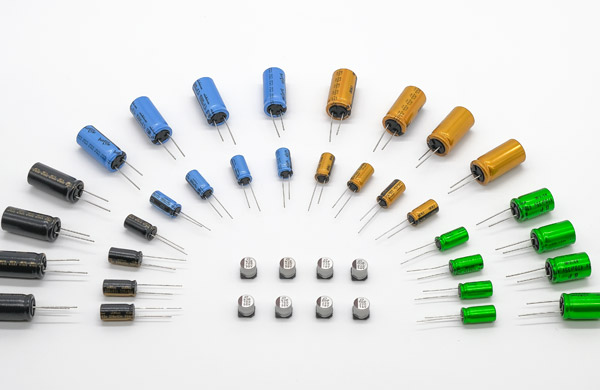

INDUSTRIAL.03Base paper for electrical and electronic materials

The moderate strength and flexibility of traditional Japanese paper allows it to be used for electrical and electronic components. For example, the paper spacer in aluminum electrolytic capacitors is mainly Manila hemp. It is special paper that prevents the mixing of electrochemically harmful substances, such as chlorine and iron particles, while performing its primary roles of preventing short circuits and retaining electrolytes.

INDUSTRIAL.04Base paper for housing and construction materials

This type of paper is used for housing and construction materials, including flooring materials, doors, and system kitchens. There are many variations including overlay paper for melamine veneers that is highly transparent and contains no shives or dust.

生活資材用原紙

LIVING MATERIALS.01Oil blotting facial paper for cosmetics

Using the gold leaf paper-making method, we create high-density paper with smooth fibers that is surprisingly effective at absorbing facial oil from the face.

LIVING MATERIALS.02Paper thread for clothing

Paper threads made from traditional Japanese paper mainly using Manila hemp come in a range of thicknesses and offer weather resistance needed for various types of clothing. They are used in a wide variety of fabrics, both knitted and woven.

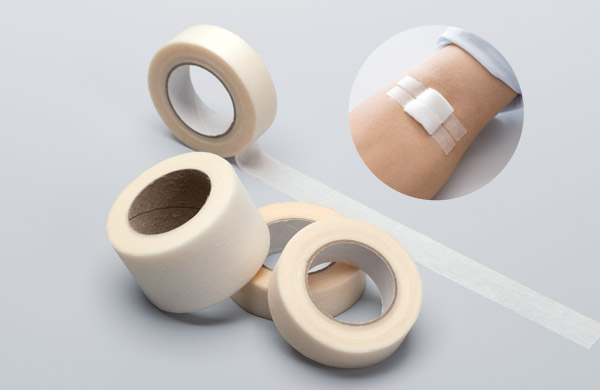

LIVING MATERIALS.03Base paper for medical tape

This paper offers the high degree of safety needed for medical applications. Such as tape for gauze and intravenous drips.

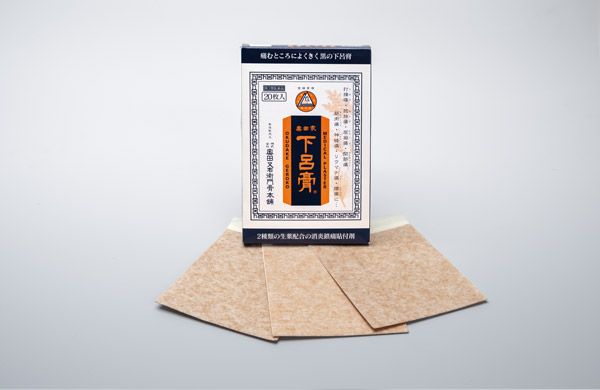

LIVING MATERIALS.04Base paper for therapeutic pads

This base paper for old-fashioned adhesive therapeutic pads. It is soft to touch and offers the distinctive soft texture of traditional Japanese paper.

LIVING MATERIALS.05Base paper for food related products

This product is the base paper for ham, which requires high heat seal ability, and for paper cooking pots, which need high heat resistance.

LIVING MATERIALS.06Wrapping paper for food products

This product is for wrapping Japanese confections and for everyday products carefully such wrapping paper benefits from the texture of traditional Japanese paper.

LIVING MATERIALS.07Anti-slip base paper

This paper has an anti-slip resin with zero adhesiveness on one or both sides, for a variety of anti-slip applications.

LIVING MATERIALS.08Paper for wrapping art

This thin, tough, soft textured base paper is made from select natural fibers. It is for storing and transporting works of art, antiques, and other precious objects.

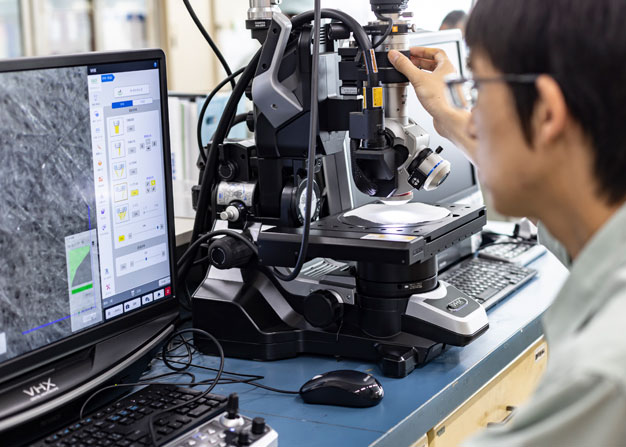

Our Research Lab Facilities

At Daifuku Paper, dedicated engineers work together with the Sales and Manufacturing Departments to develop special paper that supports industry and daily life. We have research lab facilities on the premises, so we can implement trial production of original products and performance evaluation tests based on customers’ requests. We review the results and make improvement proposals that use our experience and expertise to realize your requests.

ご相談の流れ

-

STEP.01Contacting us

We address our customer’s needs, from providing base paper to processing and finishing. To start the process, please contact us by email or by phone.

-

STEP.02Interviewing the customer

Our sales personnel will interview the customer to ask about their required application, functionality, budget, delivery schedule, and so on. (This can also be done through online videoconference or by teleconference.) Our R&D personnel could join on these discussions.

-

STEP.03Providing an estimate

Based on the customer interview, we provide an initial estimate. Providing an estimate is free of charge.

-

STEP.04Creating samples

Our sales, R&D, and production departments collaborate to consider which materials, mixing ratio, and paper-making conditions will meet the customer’s needs. Samples are then made using a test machine.

-

STEP.05Finalizing the specifications

After the customer has evaluated the samples, we create a prototype using the production machinery. Our departments collaborate on any issues that occur during actual production in order to investigate and fix them, and then we finalize the specifications.

-

STEP.06Mass production

After finishing the processes described above, we finally proceed with mass production. We also take responsibility for conducting follow-up after delivery.

Commissioned Development Q&A

- Q How long does it take from requesting development to mass production?

- A The period varies depending on the product to be developed. It is possible to start mass production from period of several months to 12 months from the initial meeting.

- Q Can I request only development?

- A Our company's policy is to consistently deliver from product development to mass production. Unfortunately, we cannot accept requests for development only.

- Q Can you possibly send prototypes overseas?

- A Although delivery fees will need to be paid, we can arrange it. Please contact us first.

- Q What kind of products are your specialties to develop?

- A We specialize in developing and manufacturing special paper with a basis weight of 20g to 30g/m2. Please contact us first for products with other basis weights.

- Q Is it possible to consult about VA/VE of existing products?

- A Yes. We will listen to your current issues and problems and propose the best solution.

会社情報

会社概要

| NAME | DAIFUKU PAPER MFG. Co., Ltd |

|---|---|

| ADDRESS | 422 MAENO, MINO-CITY, GIFU, 501-3716, JAPAN. |

| TEL/FAX | +81-575-33-2131 / +81-575-33-2135 |

| BUSINESS | SALES, R&D, MANUFACTURING OF SPECIAL PAPER |

| ESTABLISED | JANUARY IN 1934 |

| CAPITAL | 54 MILLION JPY |

| PRESIDENT | SATORU MATSUHISA |

| NUMBER OF EMPLOYEES | 100 |

沿革

| 1934 | Established with a capital of 50,000 yen. Constructed a plant at current location and started the operation of the Paper Machine No.1 |

|---|---|

| 1942 | Operated as Ministry of Finance designated plant. Produced paper for bank note and check of the Bank of Japan until 1949 |

| 1945 | Installed Paper Machine No.2 |

| 1964 | Designated as a model factory of rationalization for small and middle sized companies |

| 1966 | Installed Paper Machine No.3 |

| 1973 | Mr. Tatsuzo Matsuhisa became president and made transition to special paper maker |

| 1973 | Installed No.1 Paper Impregnation Machine |

| 1978 | Installed Paper Machine No.4 |

| 1982 | Installed No.2 Paper Impregnation Machine |

| 1991 | Installed N-No.1 Paper Impregnation Machine |

| 1995 | Mr. Toyohiko Mizuno became president |

| 1997 | Installed No.5 Paper Machine |

| 2003 | Certified ISO9001 |

| 2005 | Certified ISO14001 |

| 2009 | Mr. Toyotaro Matsuhisa became president |

| 2015 | Installed No.3 Paper Impregnation Machine |

| 2017 | Certified FSC®/CoC(FSC®C133833) |

| 2023 | Certified PEFC/CoC(SGSJP-PEFC-COC-2046) |

| 2024 | DAIFUKU PAPER MFG HOLDINGS.CO.,LTD establishment |

| 2025 | Mr. Satoru Matsuhisa became president |

ISO認証取得について

ISO 14001 certified

Environmental Policy

Meet the expectations of stakeholders and aim for our activities in harmony with global environment and local community, continue to work on Eco-friendly products development and environmental impact reduction, in addition to complying with laws and regulations and being aware of compliance, under all members can work with healthy, security and safety working place.

ISO 9001 certified

Environmental Policy

Under security and safety working environment, we act to increase Daifuku’s value by supplying our products which meet market and customer requirements, and continuing quality improvement actions through all company activities done by all members cooperation.

SDGsへの取り組み

We are actively working on 3 SDGs Goals below(12,15,17). as a SDGs promotion network member.

12. RESPONSIBLE CONSUMPTION AND PRODUCTION

15. LIFE ON LAND

17. PARTNERSHIPS FOR THE GOALS

お問い合わせ

Please feel free to contact us for special paper development consultation, prototyping, estimates, etc.

*We also consult over the phone.

PHONE. +81-575-33-2131 Office Hours 8:00 to 16:30 (Japan time)

Mon to Fri, except Japanese national and corporate holidays.

お問い合わせ

Thank you for your inquiry.